Shrink and Stretch Wrap Packaging

While it’s not uncommon to confuse stretch film and shrink film, they are two different materials made for completely...

While it’s not uncommon to confuse stretch film and shrink film, they are two different materials made for completely...

Written by:

Daryl Wallis

Posted: Jul 24, 2025 10:27:22 PM

While it’s not uncommon to confuse stretch film and shrink film, they are two different materials made for completely different applications. Wrong application of the products could result in very serious complications so it critical we understand the differences.

Both types of material are widely used to securing and protecting goods during transport and storage. Here are some winning tactics for both types of packaging.

Film selection – Choose the most suitable film for your operation based of load weight, type of product, transport method to ensure optimal protection.

Tension control – Adjust the tension of your application with ergonomic hand dispensers to ensure load stability without breaking the film or damaging the product due to over tensioning.

Even coverage – ensure the film covers the goods evenly and consistently to avoid vulnerable area that can be susceptible to damage.

Film thickness – Select the appropriate film thickness based on the size and weight of the product as well as it’s handling requirements.

Heat distribution – Ensure even heat distribution during the shrinking process to prevent weaker areas and achieve a consistent professional appearance.

Temperature control – Adjust the heat tunnel temperature accordingly to suit the different film types being used.

Staff training – Educate machine operators in effective wrapping techniques and properties of the different grades of shrink film to ensure quality and appropriate application every time.

Sealing strength – Ensure a strong and secure seal to prevent the film from opening during handling and transport.

Shrink Wrap Packaging Benefits

Stretch Film Packaging Benefits

Although plastic packaging is still one of the most used packaging materials in the world, it’s important to be aware of the impact it has on the environment.

When shrink wrap and stretch film are thrown away, they end up in landfills or the natural environment and can take hundreds of years to decompose leading to long lasting damage.

To mitigate these environmental impacts, consider using a plastic packaging that contains recycled content and is 100% recyclable. Alternatives that are biodegradable or compostable also go a long way in reducing the impact your plastic packaging has on the environment.

| Shrink Wrap | Stretch Film | |

| Materials | Plastic film designed to fit tightly around an item | Plastic film designed to stretch and cling around items |

| Application | Applied loosely then heated to shrink to the shape of the product providing protection | Applied manually or with a machine to wrap products tightly together providing stability in transport |

| Uses | Often used for individual product packaging or creating multi-packs for example in the food industry | Often used for palletising goods and securing multiple items together for transportation |

| Packaging Process | Involves sealing the film around the product and then using heat to shrink the film for a tight and sealed wrap | Applied by unrolling the film and stretching around the goods for protection and stability |

Shrink wrap can be used for a variety of items and is often the easiest way to protect irregular shaped, large items from external factors. Shrink wrap is also often used around smaller individual items in the retail or food industry.

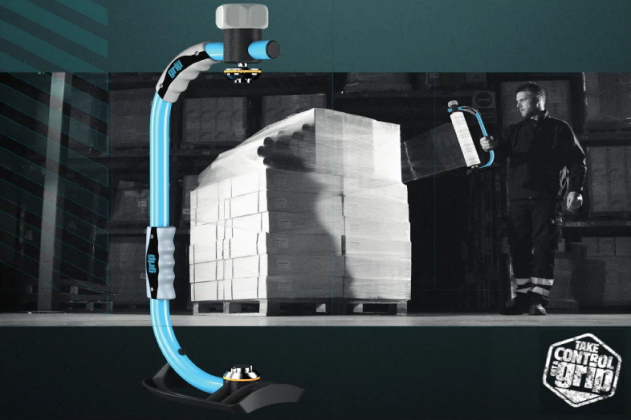

Stretch wrap is more commonly used in industrial settings such as warehouses. Often used to secure goods to a pallet, stretch film is particularly good at protecting goods that are being transported and need to be held stable.

When deciding between shrink wrap and stretch wrap there are several things you should consider:

Grip Systems offers a large selection of stretch films to suit a range of different requirements. From transparent stretch wrap to opaque and quiet stretch films there’s something for everyone.

Most packaging distributors offer a range of shrink films and equipment and will help you establish the one best suited to your operation.

Select the Right Materials for Your Product! Grip Systems has the knowledge and experience to help you design the right packaging solution for your product.