Pallet wrap recycling: 3 ways to minimise the environmental impact of your warehousing operations

Excellent load stability and safe transportation...

Excellent load stability and safe transportation...

Written by:

Ebony Holmes

Posted: Jul 24, 2025 10:26:13 PM

Excellent load stability and safe transportation of your goods is a key focus for every business. We all know how crucial it is for the products to arrive in perfect condition to enhance the customer experience.

Over the last few years, words like sustainability and environmentally friendly have began to appear more and more, with many business striving the become carbon neutral.

Here we’ll explain how to correctly recycle your used stretch film.

Pallet wrap, commonly known as stretch wrap or stretch film is one of the most well recognised packaging materials on the market today. It is used to secure goods to a pallet and protect them in transit and storage.

The short answer is, yes pallet wrap is recyclable, however it isn’t necessarily a simple process. There are a few factors to consider before throwing your waste pallet wrap in the recycling bin.

There are many ways to make your warehouse operations more environmentally friendly, especially when it comes to packaging. There’s no one size fits all when it comes to packaging and working with a supplier that can assist you with your bespoke packaging needs is so important.

Sometimes it’s difficult to avoid plastic, we get it. So that’s why it’s important to be as efficient as possible with your plastic packaging. One of the most effective ways to be more efficient is to reduce the usage. This could be by switching to a stronger pallet wrap and using less of it, or using a thinner, pre-stretched film rather than a thicker conventional wrap.

Paper stretch wraps are now available however these are very costly as not yet as effective as plastic wrap if you’re main objective is load security and pallet stability.

Most protective packaging such as bubble wrap and void fill is available in paper from most packaging distributors worldwide. Generally these work just as well and are great alternatives to plastic packaging.

Ensuring that you recycle the

plastic packaging you do use goes a long way in reducing the environmental

impact of your warehouse packaging. Ensure the packaging you use is accepted by

the local recycling program and you dispose of it correctly.

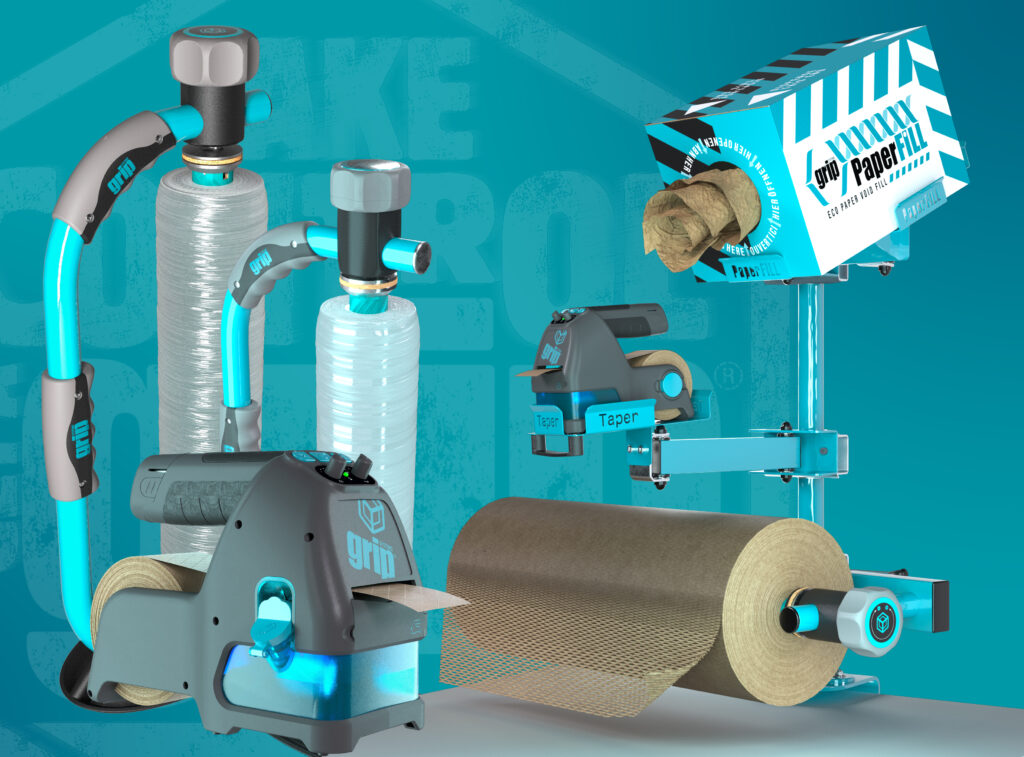

Making use of technology in packaging can help contribute to a sustainable warehouse packaging environment. There are several ways you can utilise packaging technology including automated packaging systems to optimise material usage and reduce waste.

Automatic machines and packaging systems can be used to exactly fit each item, minimising the unnecessary need for excess materials.

Specially formulated with a unique blend of polyethylene, Grip Film is high performance pre-stretched film designed to increase the holding force and stability of a pallet whilst using the minimum amount of film possible.

Pre-stretched pallet wrap is a type of stretch film that is commonly used in warehouse operations all over the world. It gets it’s name from the manufacturing process where the film is stretched to almost breaking point. When used in conjunction with the Grip Applicator, here are some benefits you can expect from Grip Film.

In the pursuit of a greener future, the UK has been actively promoting more sustainable practices, including the recycling of packaging materials such as pallet wrap. As pallet wrap is a widely used material it’s disposal can contribute to plastic waste and environmental damage if the disposal is not correctly managed.

Dedicated recycling bins and partnerships with waste management companies facilitate the collection of used pallet wrap, ensuring it’s separation from other waste streams. The collected stretch wrap undergoes sorting and processing, where it is transformed into recycled plastic pellets. These materials are repurposed in various plastic products that contain recycled content.

Pallet wrap recycling allows organisations to significantly mitigate the environmental impact of warehouse operations. Embracing these sustainable practices not only aligns with the movement towards a greener future, but also presents opportunities for cost savings and improved efficiencies.

Together, we can achieve a sustainable future without compromise on quality.